Roller-compacted concrete (RCC)

Roller-compacted concrete (RCC)

Valid concrete is a modern construction material used for the construction of pavement structures and base concrete. Its technological adaptability and efficiency make it an extremely suitable solution for various types of infrastructure. The composition of valid concrete is similar to that of regular concrete but with a higher proportion of aggregate and a specific method of installation using standard asphalt paving machines. Valid concrete is becoming increasingly popular in contemporary and developed economies due to its numerous advantages, including durability, speed of execution, and environmental friendliness. It is used in various fields, from local roads to industrial zones, offering a long-lasting and economical choice for the construction of roads and other traffic surfaces.

What is Roller-compacted concrete (RCC)?

Roller-compacted concrete (RCC), also known as valid compacted concrete (RCC), is a specific type of concrete that differs in its method of installation. Unlike regular concrete, which is vibrated, valid concrete is installed by compacting and rolling. This process requires a special mix that is stiff enough not to deform during installation but also homogeneous to allow proper distribution of the cement paste and cement hydration. The materials that make up valid concrete are aggregate, cement, water, and various additives such as fly ash and chemical admixtures, which improve the workability and durability of the concrete. The main difference compared to regular concrete is the higher proportion of fine aggregate particles and a smaller amount of cement. The installation process of valid concrete includes substrate preparation, transportation, compaction with pavers and rollers, cutting the pavement, and curing the concrete, resulting in a durable and resilient pavement structure.

Advantages

The use of Roller-compacted concrete (RCC) brings numerous advantages, including cost-effectiveness, environmental friendliness, and durability:

- Cost-Effectiveness: Valid concrete is cost-effective due to its low initial costs, long lifespan, and minimal maintenance expenses. Installation does not require reinforcement, formwork, or anchors, which reduces labor and execution time. The speed of installation allows for quick opening to traffic, even during colder periods of the year.

- Environmental Friendliness: The production of Roller-compacted concrete (RCC) requires less energy compared to asphalt, reducing CO2 emissions. Concrete can be recycled and reused as a construction material, and production plants are less polluting. Additionally, concrete reflects more light, reducing the need for public lighting.

- Durability: It is highly resistant to wear, freezing, salt, chemicals, and climatic changes. Its strength increases over time thanks to the cement hydration process. Pavement structures made of valid concrete maintain smoothness and reduce the occurrence of ruts and water buildup, ensuring safer driving.

- Safety: The surface of Roller-compacted concrete (RCC) provides better visibility at night, reduces the possibility of slipping, and minimizes water retention on the pavement. It maintains pavement smoothness in the long term, reducing maintenance costs and increasing driving comfort and safety.

These characteristics make valid concrete an ideal solution for various types of infrastructure, from roads to industrial zones, providing a long-lasting, economical, and environmentally friendly choice.

Production Process

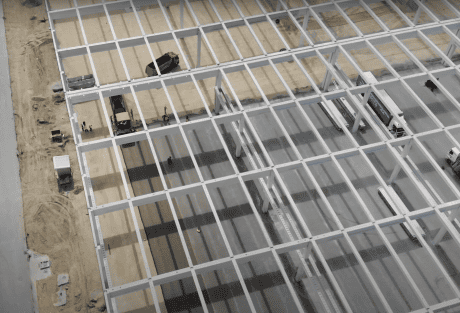

The production process of Roller-compacted concrete (RCC) is specific and includes several key stages to ensure a high-quality and long-lasting pavement structure. First, substrate preparation is essential, involving leveling and compacting the ground to create a solid foundation for the concrete. Next, the concrete mix is produced in concrete plants, where aggregate, cement, water, and additional additives such as fly ash are used to improve the workability and durability of the concrete.

The transportation of concrete to the construction site is done with dump trucks, and the concrete is installed using pavers that evenly distribute the mix. The key stage of installation is the compaction of the concrete, which is carried out with various types of rollers to ensure the necessary density, strength, and surface texture. Finally, cutting the pavement and creating control joints ensure crack control and extend the pavement’s lifespan.

Environmental Aspect

The environmental aspect of valid concrete is a significant advantage compared to other construction materials. Production requires less energy compared to asphalt, directly reducing CO2 emissions. Concrete can be recycled and reused as a construction material, reducing the need for new resources and environmental pollution.

Concrete pavements reflect more light than asphalt, reducing the need for public lighting and energy consumption. The surface texture of valid concrete can be treated to reduce noise, which is particularly important in urban areas. Additionally, concrete pavements heat up less during summer, reducing the urban heat island effect and the need for air conditioning. All these characteristics make valid concrete an environmentally friendly and sustainable solution for modern infrastructure.

Economic Justification

Compared to other pavement construction solutions, Roller-compacted concrete (RCC) is the most cost-effective due to its low initial execution costs, long lifespan, and minimal maintenance expenses. The installation process does not require the use of reinforcement, formwork, or anchors, further reducing costs and the need for labor. The speed of execution allows for quick opening to traffic of completed sections, even in adverse weather conditions, thereby reducing additional costs.

Concrete pavements reflect more light, reducing public lighting costs. Additionally, the longevity and minimal maintenance requirement of valid concrete reduce overall costs throughout the pavement’s lifecycle. Due to the rigidity of the concrete, deformations are minimal, resulting in lower costs for repairs and reconstruction. All these factors contribute to valid concrete being the most economically acceptable solution for the construction of various types of pavement structures.